Driving Efficiency and Continuous Improvement in Indian Business: Embracing Kaizen and Lean Principles

- February 22, 2024

- Posted by: bhushanpungliya

- Categories:

In today’s fiercely competitive business landscape, the pursuit of operational excellence and continuous improvement has become imperative for sustained success. Among the methodologies that have gained widespread recognition for their transformative impact on businesses worldwide are Kaizen and Lean principles. These philosophies, originating from Japan, have revolutionized the way organizations approach productivity, efficiency, and quality. Their adoption in Indian businesses has shown promising results, contributing significantly to their growth and competitiveness.

Understanding Kaizen and Lean Principles

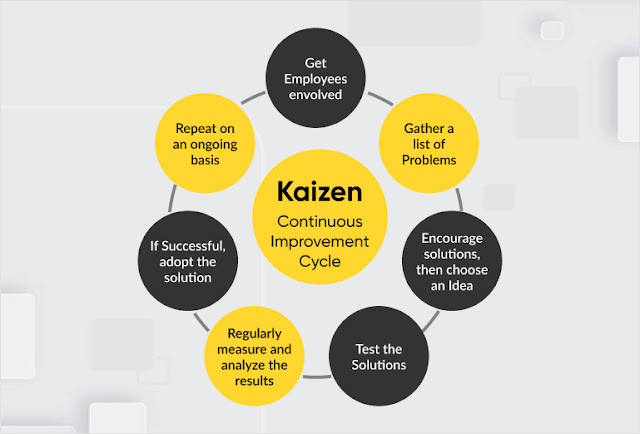

Kaizen: The Philosophy of Continuous Improvement

Kaizen, rooted in the Japanese philosophy of continual improvement, emphasizes small, incremental changes implemented by every employee. It revolves around the notion that even minor, ongoing improvements in processes, systems, and workflows can lead to significant enhancements in productivity, quality, and customer satisfaction. Kaizen fosters a culture of continuous learning, involvement, and empowerment at all levels of an organization.

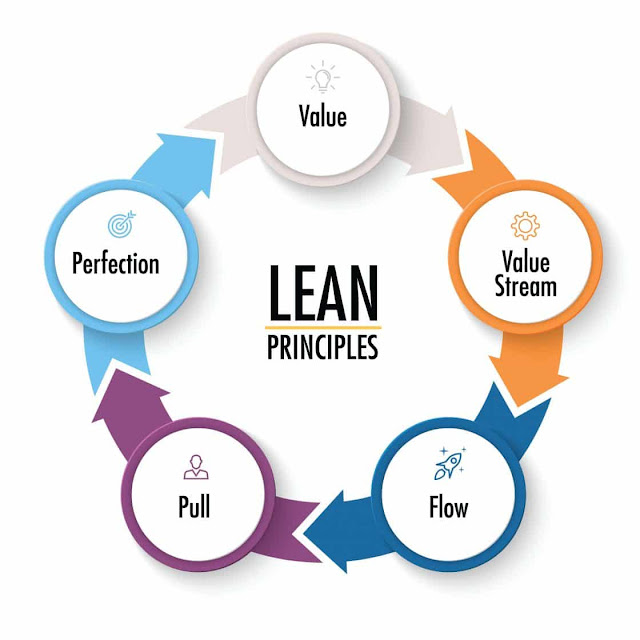

Lean Methodology: Streamlining Processes for Efficiency

Lean principles, derived from the Toyota Production System, focus on eliminating waste, optimizing processes, and maximizing value for customers. It entails identifying and eliminating non-value adding activities, such as overproduction, waiting times, unnecessary inventory, defects, and excessive motion. Lean aims to create a more efficient, agile, and customer-centric organization by promoting a culture of problem-solving and waste reduction.

Impact on Indian Business:

Impact of Kaizen and Lean in Indian Business

- Enhancing Operational Efficiency: The implementation of Kaizen and Lean methodologies has enabled Indian businesses to streamline their operations, reduce inefficiencies, and enhance productivity. By empowering employees to identify and address issues at the grassroots level, these principles foster a culture of innovation and efficiency.

- Improving Quality and Customer Satisfaction: Through a relentless focus on eliminating waste and improving processes, businesses in India have significantly enhanced the quality of their products and services. This heightened quality not only satisfies customers’ expectations but also boosts brand reputation and loyalty.

- Cost Reduction and Sustainable Growth: Kaizen and Lean methodologies emphasize cost-effectiveness by minimizing unnecessary expenditures and optimizing resources. This approach enables businesses to achieve sustainable growth by investing resources efficiently and driving profitability.

Approaches for Implementing Kaizen and Lean Principles in Indian Businesses

- Cultural Transformation and Employee Engagement: The successful adoption of Kaizen and Lean requires a cultural shift within organizations. Leaders must foster an environment that encourages employee participation, empowerment, and open communication. Training programs and workshops can educate employees about these methodologies and instill a mindset of continuous improvement.

- Value Stream Mapping and Process Optimization: Conducting thorough value stream mapping helps identify inefficiencies and bottlenecks in processes. By streamlining workflows and eliminating waste, businesses can optimize their operations, enhance efficiency, and deliver greater value to customers.

- Leadership Commitment and Continuous Evaluation: Sustaining the benefits of Kaizen and Lean practices necessitates unwavering commitment from leadership. Regular evaluations, key performance indicators, and continuous feedback mechanisms are vital for monitoring progress and making necessary adjustments.

- Adaptability: Indian businesses must adapt these methodologies to suit their unique cultural, operational, and market contexts.

- Challenges: Addressing potential challenges such as resistance to change, resource constraints, and cultural barriers is vital for successful implementation.

- Sustainability: Ensuring the sustainability of improvements by embedding these methodologies into the organizational DNA is crucial for long-term success.